Popular keywords:

Contacts:Mr.Zhong

Email:121740864@qq.com

Phone:+86-138-1293-0229

ADD:579 Qianjin East Road, Kunshan Development Zone, Jiangsu Province

A.【Application】:

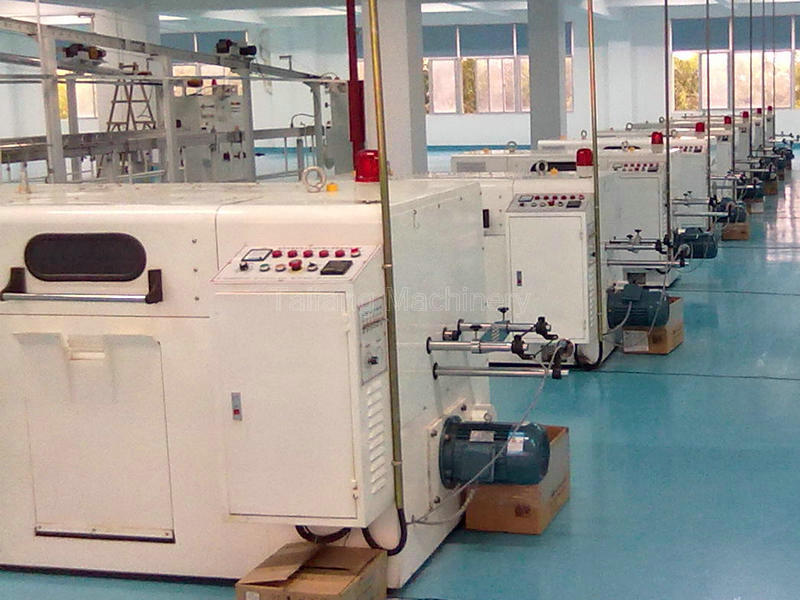

Our company is a well-known professional manufacturer of high-speed stranded wire machines in the industry. After years of development and production, we have formed a complete series of mature models to meet the different professional needs of various customers. The series of models are exquisitely designed, mature in technology, reasonable in structure, stable in operation, excellent in quality, energy-saving and efficient, and are highly praised by various customers, It can be widely used for stranding various soft/hard conductor wires (copper wire, enameled wire, tinned wire, copper clad steel, copper clad aluminum, etc.) and electronic wires, such as power lines, telephone lines, audio lines, video lines, automotive lines, network lines, etc.

B.【Technique Feature】:

1. The maximum speed of the spindle is 3000-4500rpm.

2. Automatic tension control: When stranding, the tension of the take-up wire needs to continuously increase when it receives a full reel from the bottom of the reel. This function automatically tracks and adjusts the tension of the take-up wire; Make the tension of the entire reel uniform and consistent, and at the same time, this machine can adjust the tension without stopping the machine.

3. The main engine is lubricated with butter and cooled naturally, effectively extending the service life of the spindle bearings.

4. The wire passing system adopts a new structure, where the wire passes directly from the spindle guide wheel to the bow belt, reducing the scratches and jumping caused by the failure of the angle guide wheel on the aluminum plate.

5. Three compression devices are installed inside the machine to ensure the roundness of the conductors after twisting and reduce the loss of insulation materials

6. The entire machine adopts synchronous belt transmission, with no lubrication points inside the machine, keeping the machine clean and the stranded wire free of oil stains. It is suitable for conductor stranding of various types of wire with high surface cleanliness requirements.

7. To adjust the lay distance, only one change gear needs to be replaced, and to adjust the lay direction, only the reversing lever needs to be pulled, making the operation simple and reducing the operator's error rate and work intensity. The bearings of the entire machine are all made of well-known Japanese brands, and the bow belt is made of new spring steel material, which has good flexibility and avoids jumping caused by vibration during high-speed operation. The frequency converter, PLC, magnetic powder clutch, electromagnetic brake, hydraulic jack, etc. are all imported well-known brands, reducing failure rates and maintenance costs.

C.【Technique specifications】:

| Machinery type | TF-200P | TF-300P | TF-500P/400P | TF-630P |

| Application | Suitable for stranding of bare stranded wires, tinned wires , copper clad aluminum, enameled wires, alloy wires, etc. | |||

| Rotary Speed | 4000rpm | 3000rpm | 3000rpm | 1800rpm |

| Min wire OD | φ0.025 | φ0.05 | φ0.08 | φ0.23 |

| Max wire OD | φ0.12 | φ0.28 | φ0.45 | φ0.64 |

| Min specification | 0.005mm2 | 0.035mm2 | 0.035mm2 | 0.8mm2 |

| Max specification | 0.08mm2 | 0.45mm2 | 2.0mm2 | 6.0mm2 |

| Min pitch | 0.8 | 4.36 | 5.68 | 11.15 |

| Max pitch | 10.6 | 17.17 | 57.00 | 60.24 |

| Coil OD | 200 | 300 | 500 | 630 |

| Coil outer width | 134 | 134 | 320 | 375 |

| Coil inner hole | 30 | 30 | 56 | 80 |

| Drive Motor | 3HP | 5HP | 7.5HP | 10HP |

| Long | 1900 | 2455 | 2560 | 2850 |

| Wide | 750 | 1080 | 1350 | 1500 |

| High | 950 | 1102 | 1400 | 1660 |

| Twisting direction | S/Z commutation can be freely selected | |||

| Flat Cable | Bearing type cable arrangement, with adjustable spokes and spacing | |||

| Braking | Adopting electromagnetic brake, with internal and external broken wires and automatic braking when reaching the meter | |||

| Tension control | The magnetic powder clutch controls the tension of the take-up line, and the tension is automatically adjusted by a PLC program controller to maintain a constant tension | |||